What is OTEC?

It is ideally suited to warm tropical waters such as those found in the Philippines and countries along the equatorial belt, particularly those with deep ocean close to land and with legacy polar currents at depth. The ideal surface water temperature is 28 degrees Celsius while the ideal cold water temperature is 5 deg Celsius at 1000 m deep.

To produce electricity a differential minimum of 20 degrees Celsius is necessary. The higher the difference the more power it can generate.

Due to the relatively low temperature differentials, OTEC requires high engineering skills. Although the technology has been proven in small pilot plants the upfront development costs remain high but large pre-commercial production as the next level of development may be feasible with government support measures such as Feed-in Tariff.

OTEC’s major advantage when compared to other renewable energies is its potential to produce electricity reliably and at a constant rate all year round. Additionally as a primarily offshore installation it has minimal onshore impact.

How does it work? There are three (3) basic designs to generate electricity:

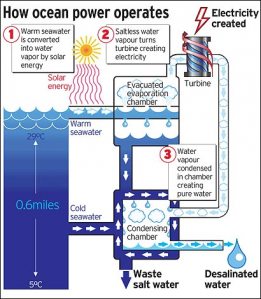

Open Cycle OTEC as represented in the diagram above produces drinking water as by-product. Warm sea water is introduced into an evaporation chamber to remove the salt in the water and generate steam like the hot air you get when a kettle boils. The hot air then powers a turbine and create electricity. After it powers the turbine it is then collected into a condensing chamber which is cooled by the water from the deep ocean. This turns the hot air back into liquid producing desalinated water which can be used as drinking water.

In Closed Cycle OTEC warm surface water is used to heat a working fluid such as ammonia. It boils at low temperature without the need for firing and create vapours to drive a turbine. Using the cold water from deep ocean the working fluid is then cooled back to its liquid state so that the warm surface water can heat it again to repeat the process. No desalinated water is produced as by-product.

One can combine both features in Closed and Open Cycle using Hybrid Cycle OTEC.

In a hybrid cycle the warm surface water is introduced into an evaporation chamber to generate steam – just like the Open Cycle. The steam produced is then used to heat and vapourise the working fluid to drive the turbine and produce electricity. Just like the Closed Cycle the working fluid is then cooled by deep ocean water back to its liquid state. It is then possible to condense the steam from the warm surface water to produce drinking water.